close

Choose Your Site

Global

| Availability: | |

|---|---|

| Quantity: | |

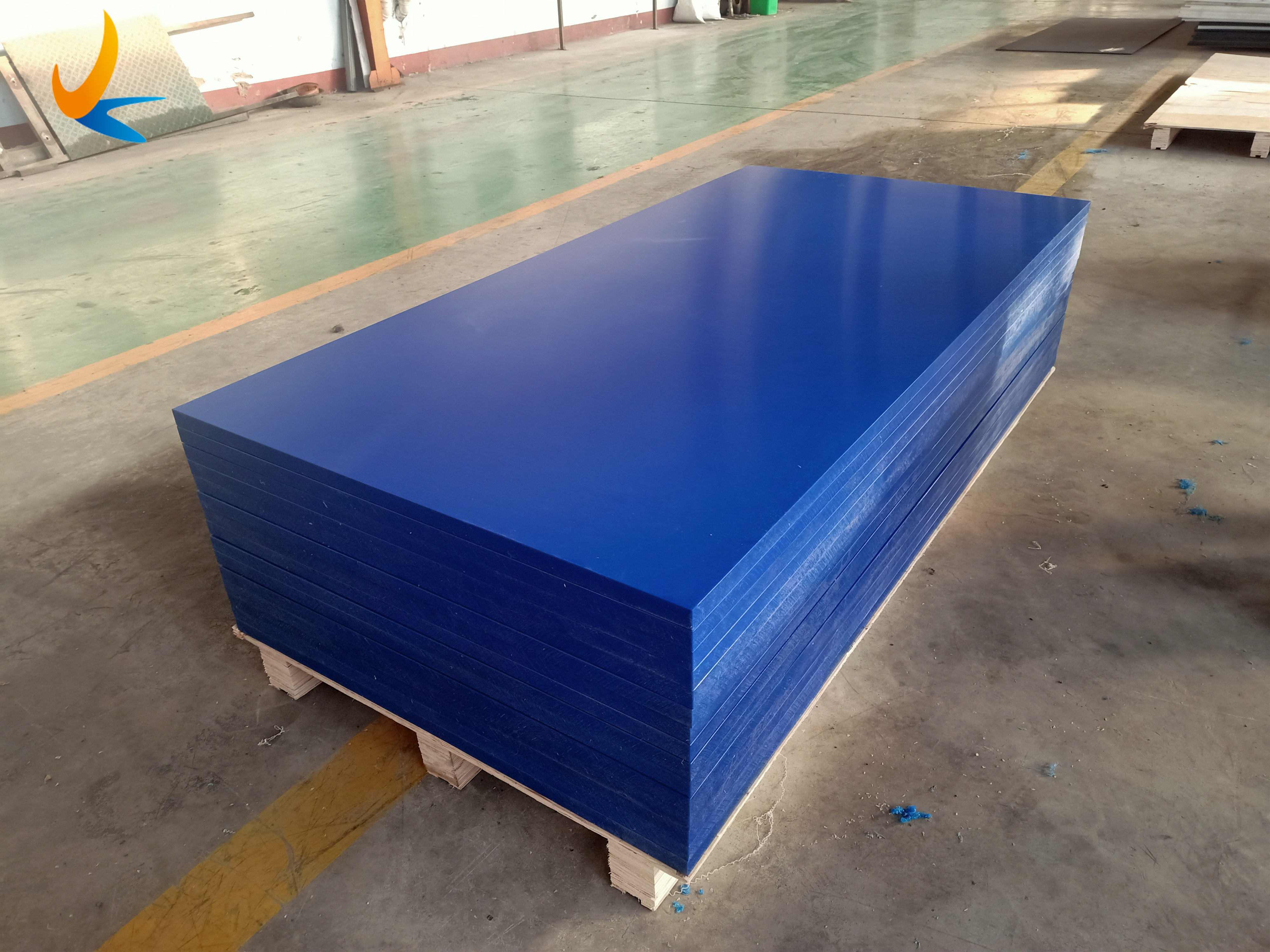

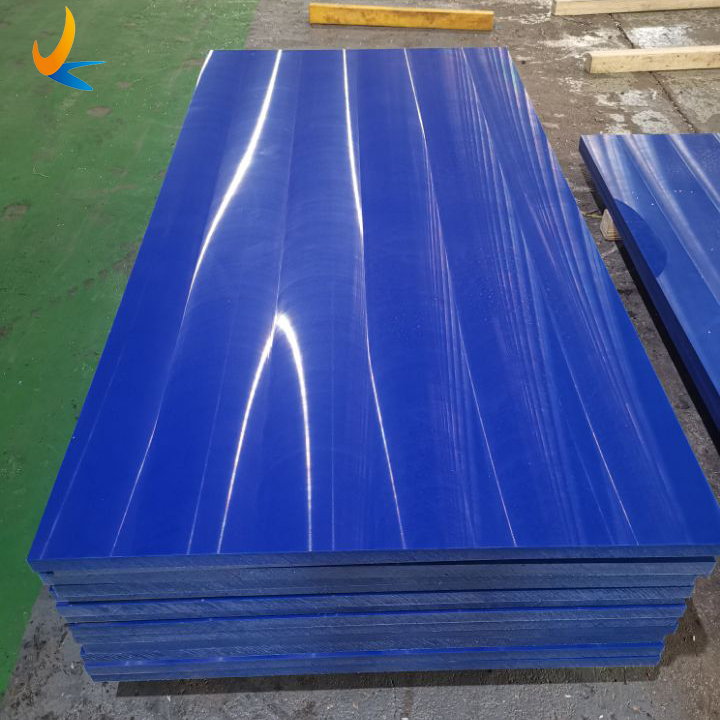

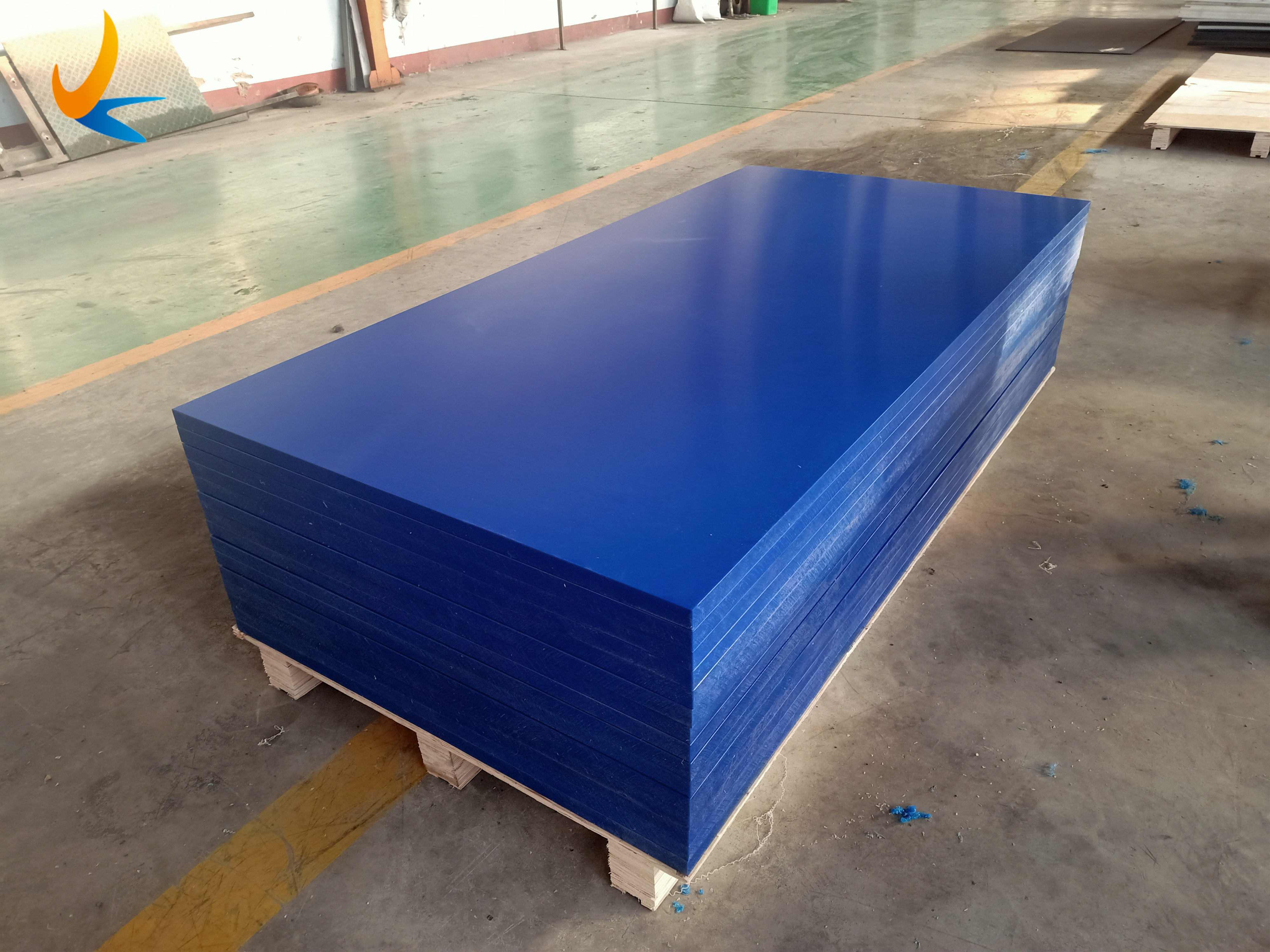

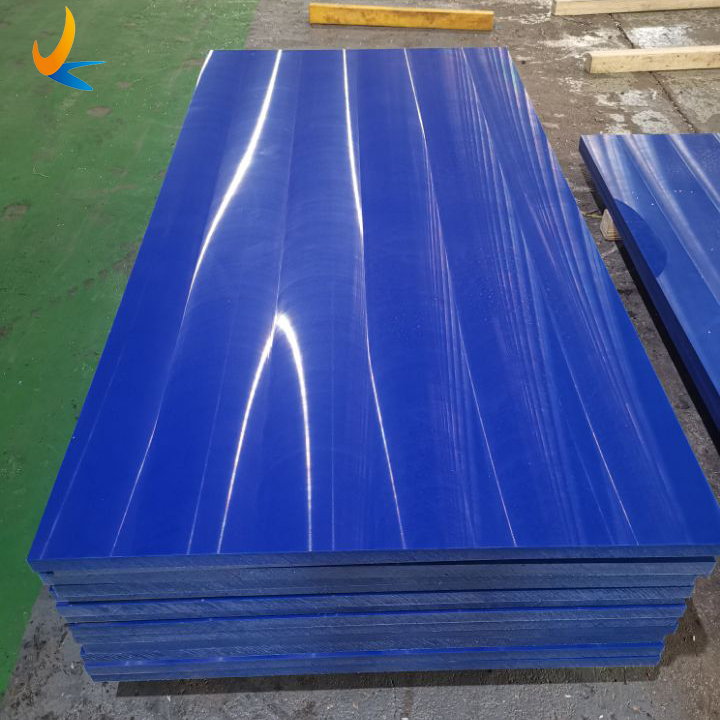

UHMW PE 1000 Sheet

Xinxing

Free sample available!

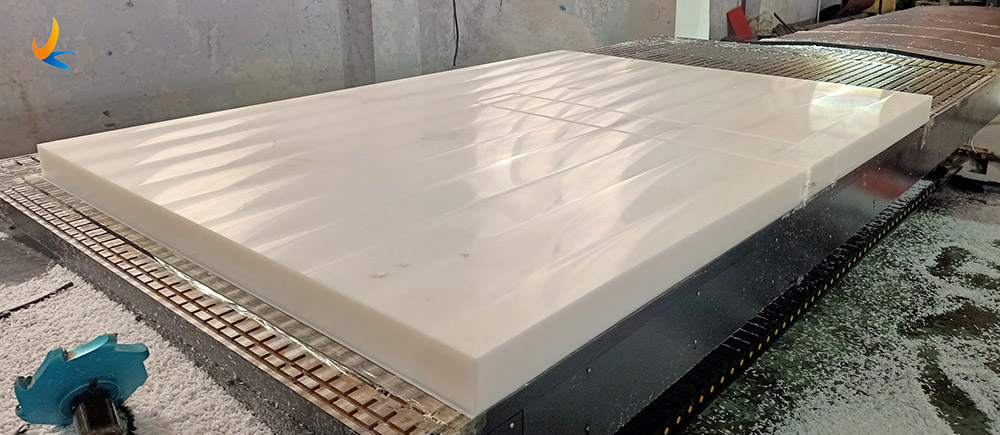

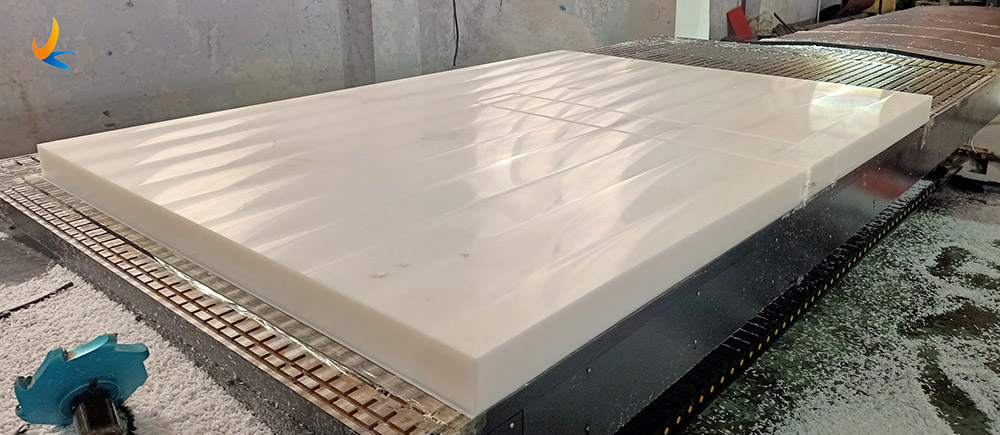

Ultra High Molecular Weight Polyethylene UHMW PE1000 Sheet

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) sheet is a very tough material, with the highest impact strength of any thermoplastic presently made.

UHMW PE1000 sheet is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents.

UHMW PE1000 sheet is highly resistant to corrosive chemicals; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating; and is highly resistant to abrasion, in some forms being 15 times more resistant to abrasion than carbon steel. Its coefficient of friction is significantly lower than that of nylon and acetal and is comparable to that of polytetrafluoroethylene (PTFE, Teflon), but UHMW PE1000 has better abrasion resistance than PTFE.

Specifications:

| SIZE (MM) | THICKNESS (MM) | |

| STANDARD | 5040*1330 | 2-300 |

| STANDARD | 4730*1230 | 2-300 |

| STANDARD | 3050*1220 | 2-300 |

| STANDARD | 6050*1820 | 2-300 |

| STANDARD | 3030*1550 | 2-300 |

| STANDARD | 4520*2000 | 2-300 |

| STANDARD | 3050*3050 | 2-300 |

| STANDARD | 2000*1000 | 2-300 |

| STANDARD | 6000*2000 | 2-300 |

| Other size and thickness can be customized. | ||

| Material Properties | Standard | Unit | Value |

| Average molecular weight | g /mol | Approx 4.5-6 million | |

| Density | ISO1183 | Kg/m3 | 922-942 |

| Water absorption at 23℃until saturation | ISO62 | % | <0.01 |

| Material Properties | Standard | Unit | Value |

| Tensile stress at yeild (tensile strength) | ISO527 | MPa | ≥17 |

| Enlongation at break | ISO527 | % | ≥300 |

| Tensile modulus | ISO527 | MPa | ≥700 |

| Impact strength (Charpy)at 23℃ | ISO179 | Kj/m2 | No break |

| Notched impact strength (Charpy)at 23℃ | ISO11542-2 | Kj/m2 | ≥80 |

| Ball indentation hardness | ISO2039-1 | N/mm2 | 30-35 |

| Shore-Hardness D,15 s value | ISO868 | 60-65 | |

| Coefficient of friction | Approx.0.2 | ||

| Abrasion(Sand-Slurry) | 80 | ||

| Themal properties | Standard | Unit | Value |

| Melting point DSC ,10k/min | ISO3146 | ℃ | 135-138 |

| Vicat softening point | ISO306 | ℃ | 80 |

| Coefficient of linear themal expansion Between 23 and 80℃ | ISO11359 | K-1 | approx 2*10-4 |

| Themal conductivity | ISO52612 | W/[m*k] | approx 0.4 |

| Use Temperature (max.) | ℃ | 80 | |

| Use Temperature (briefly) | ℃ | 90 | |

| Use Temperature (min.) | ℃ | -200 | |

| Electrical properties | Standard | Unit | Value |

| Relative permitivity at 100 Hz | IEC 60250 | - | 2.1 |

| Dissipation factor at 100 Hz | IEC60250 | - | 3.9*10-4 |

| Volume resistivity | IEC60093 | Ohm*m | >1012 |

| Surface resistivity | IEC60093 | Ohm | >1012 |

| Dielectric strength | IEC60243 | KV/mm | 45 |

The information contained in this technical date sheet can not be constructed as a promise or guarantee of specific properties of our products.Any determination of suitability of a particular material and part design for any use contemplated by the user is the sole responsibility of the user. The information contained in this technical date sheet is based on present knowledge and may be subject to change without further notice.

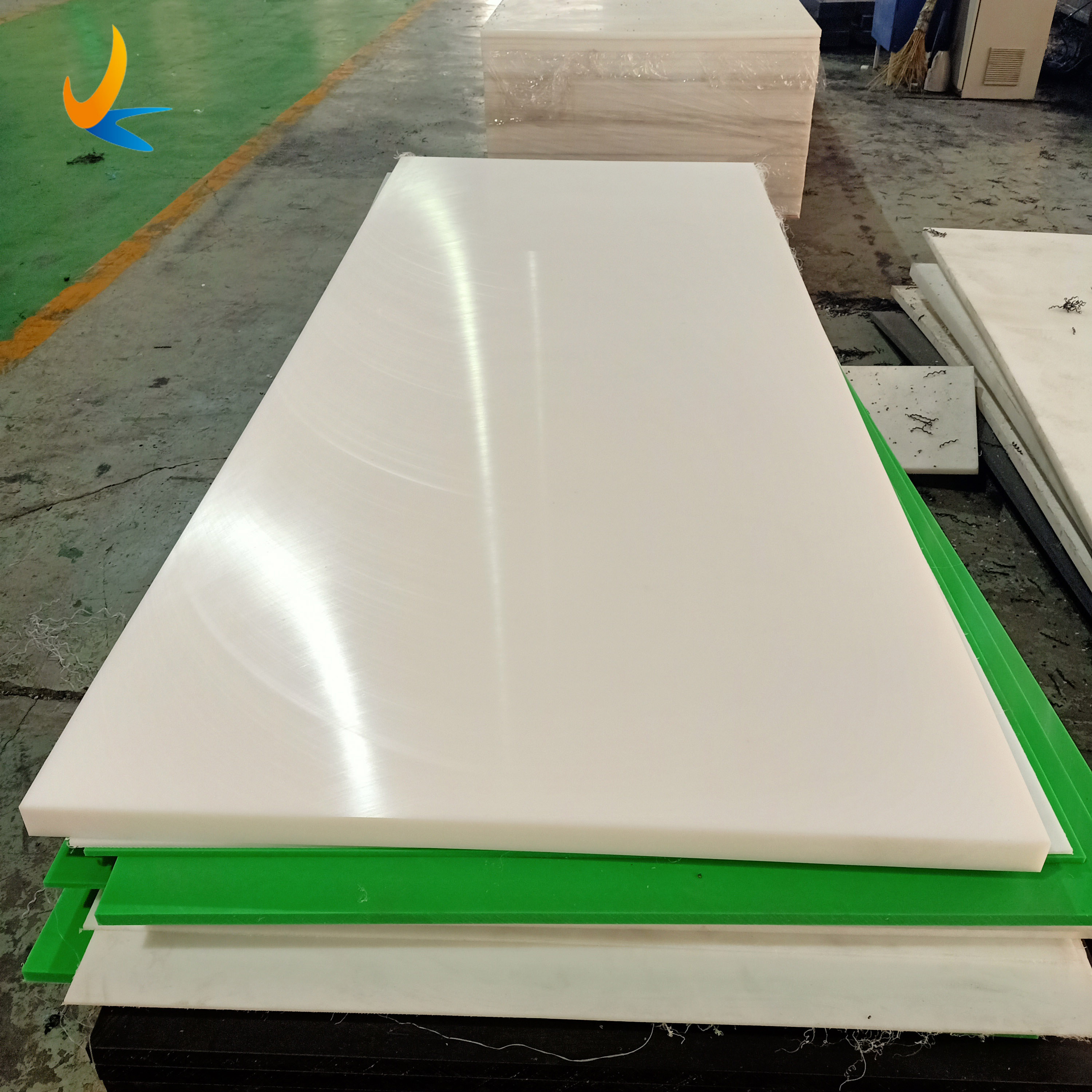

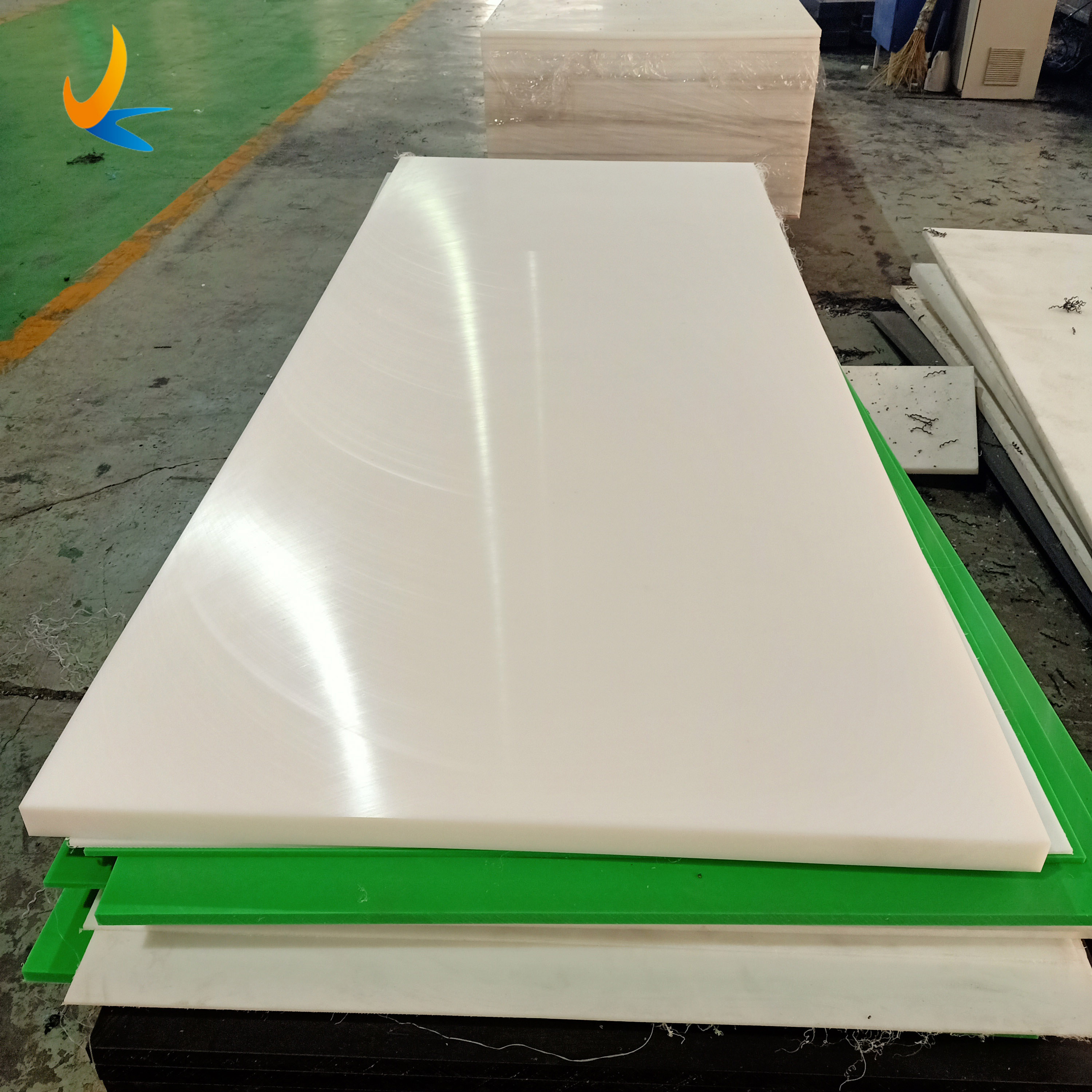

UHMW PE1000 Dual Color Sheet for Option

partitioning tables, countertops and chopping boards PE, butcher blocks, logs in the meat industry (slaughterhouses, butchers, butcher shops, shops of meat processing, poultry, fish) and food

fenders, fender moldings, protective and sliding for ships and boats in ports, shipyards

gears, machine parts and components, self-lubricating gears, guides, slides, bearing housings, plain sleeves

doors in factories, cold stores, refrigerators , rubbing strips

sieves, colanders, presses (eg paper industry)

undercoats for core cutters

sprockets, guides

canning lines and bottlers elements of the lines of bottling, sorting, packaging and packing

lining of chutes, ramps, bleed, hold, transfer stations (sand, coal, grain and other bulk materials), silos, wagons, truck trailers

bulk materials industry

paper, printing, textile industry

chemically resistant pump components (casings, impellers), fans, filters

sporting articles for use in water

Plastic bearings

|  |  |  |

| HDPE Engraving Board | Composite Ground Mat | Composite Outrigger Pad | Dasher Board for Rink |

Free sample available!

Ultra High Molecular Weight Polyethylene UHMW PE1000 Sheet

Ultra-high-molecular-weight polyethylene (UHMWPE, UHMW) sheet is a very tough material, with the highest impact strength of any thermoplastic presently made.

UHMW PE1000 sheet is odorless, tasteless, and nontoxic. It embodies all the characteristics of high-density polyethylene (HDPE) with the added traits of being resistant to concentrated acids and alkalis, as well as numerous organic solvents.

UHMW PE1000 sheet is highly resistant to corrosive chemicals; has extremely low moisture absorption and a very low coefficient of friction; is self-lubricating; and is highly resistant to abrasion, in some forms being 15 times more resistant to abrasion than carbon steel. Its coefficient of friction is significantly lower than that of nylon and acetal and is comparable to that of polytetrafluoroethylene (PTFE, Teflon), but UHMW PE1000 has better abrasion resistance than PTFE.

Specifications:

| SIZE (MM) | THICKNESS (MM) | |

| STANDARD | 5040*1330 | 2-300 |

| STANDARD | 4730*1230 | 2-300 |

| STANDARD | 3050*1220 | 2-300 |

| STANDARD | 6050*1820 | 2-300 |

| STANDARD | 3030*1550 | 2-300 |

| STANDARD | 4520*2000 | 2-300 |

| STANDARD | 3050*3050 | 2-300 |

| STANDARD | 2000*1000 | 2-300 |

| STANDARD | 6000*2000 | 2-300 |

| Other size and thickness can be customized. | ||

| Material Properties | Standard | Unit | Value |

| Average molecular weight | g /mol | Approx 4.5-6 million | |

| Density | ISO1183 | Kg/m3 | 922-942 |

| Water absorption at 23℃until saturation | ISO62 | % | <0.01 |

| Material Properties | Standard | Unit | Value |

| Tensile stress at yeild (tensile strength) | ISO527 | MPa | ≥17 |

| Enlongation at break | ISO527 | % | ≥300 |

| Tensile modulus | ISO527 | MPa | ≥700 |

| Impact strength (Charpy)at 23℃ | ISO179 | Kj/m2 | No break |

| Notched impact strength (Charpy)at 23℃ | ISO11542-2 | Kj/m2 | ≥80 |

| Ball indentation hardness | ISO2039-1 | N/mm2 | 30-35 |

| Shore-Hardness D,15 s value | ISO868 | 60-65 | |

| Coefficient of friction | Approx.0.2 | ||

| Abrasion(Sand-Slurry) | 80 | ||

| Themal properties | Standard | Unit | Value |

| Melting point DSC ,10k/min | ISO3146 | ℃ | 135-138 |

| Vicat softening point | ISO306 | ℃ | 80 |

| Coefficient of linear themal expansion Between 23 and 80℃ | ISO11359 | K-1 | approx 2*10-4 |

| Themal conductivity | ISO52612 | W/[m*k] | approx 0.4 |

| Use Temperature (max.) | ℃ | 80 | |

| Use Temperature (briefly) | ℃ | 90 | |

| Use Temperature (min.) | ℃ | -200 | |

| Electrical properties | Standard | Unit | Value |

| Relative permitivity at 100 Hz | IEC 60250 | - | 2.1 |

| Dissipation factor at 100 Hz | IEC60250 | - | 3.9*10-4 |

| Volume resistivity | IEC60093 | Ohm*m | >1012 |

| Surface resistivity | IEC60093 | Ohm | >1012 |

| Dielectric strength | IEC60243 | KV/mm | 45 |

The information contained in this technical date sheet can not be constructed as a promise or guarantee of specific properties of our products.Any determination of suitability of a particular material and part design for any use contemplated by the user is the sole responsibility of the user. The information contained in this technical date sheet is based on present knowledge and may be subject to change without further notice.

UHMW PE1000 Dual Color Sheet for Option

partitioning tables, countertops and chopping boards PE, butcher blocks, logs in the meat industry (slaughterhouses, butchers, butcher shops, shops of meat processing, poultry, fish) and food

fenders, fender moldings, protective and sliding for ships and boats in ports, shipyards

gears, machine parts and components, self-lubricating gears, guides, slides, bearing housings, plain sleeves

doors in factories, cold stores, refrigerators , rubbing strips

sieves, colanders, presses (eg paper industry)

undercoats for core cutters

sprockets, guides

canning lines and bottlers elements of the lines of bottling, sorting, packaging and packing

lining of chutes, ramps, bleed, hold, transfer stations (sand, coal, grain and other bulk materials), silos, wagons, truck trailers

bulk materials industry

paper, printing, textile industry

chemically resistant pump components (casings, impellers), fans, filters

sporting articles for use in water

Plastic bearings

|  |  |  |

| HDPE Engraving Board | Composite Ground Mat | Composite Outrigger Pad | Dasher Board for Rink |